Westport, Volvo HPDI joint venture provides compelling way to eliminate emissions

Volvo Group recently formed a joint venture with Westport Fuel Systems, through which it acquired assets related to Westport’s high-pressure direct injection (HPDI) fuel system for US$28 million, and up to US$45 million more based on its performance.

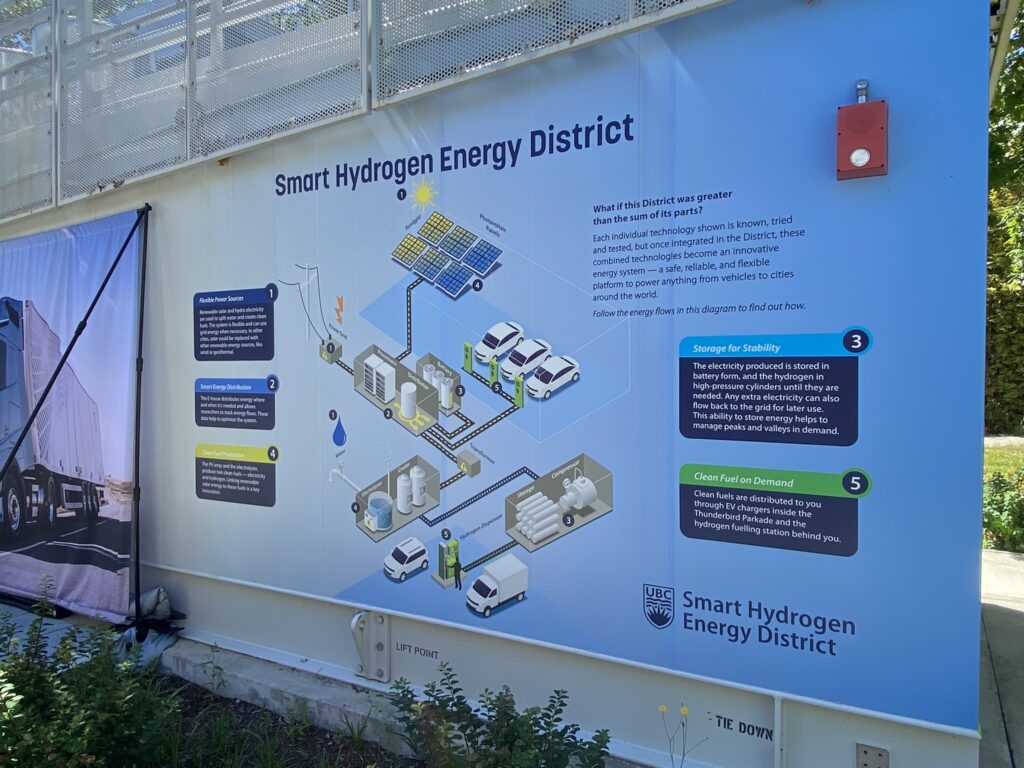

And on July 4, officials from both companies and special guests gathered at University of B.C. – birthplace of the technology – to celebrate the new venture.

“HPDI technology was originated here at UBC as a means to reduce the fuel costs and emissions of diesel-powered vehicles with diesel engines, without any compromises – no degradation whatsoever – and all the characteristics and traits that have made the diesel engine the workhorse of industry globally for many decades,” said Scott Baker, vice-president, product development and technology officer of the yet-to-be-named JV.

“Our mandate is to accelerate and further develop the commercialization and global adoption of the HPDI fuel system.”

Born at UBC

About 60% of Westport engineers – and Baker himself — are graduates of UBC, and the school recently built a hydrogen fueling station for heavy trucks, where a Volvo FH was displayed. It featured Westport’s HPDI fuel system – commercially available in Europe fueled by natural gas — reconfigured to run off hydrogen. The base engine was unchanged, Baker noted.

“The fuel system refers to the fuel storage tanks, the fuel pumps, the fuel injectors and the associated fuel pressure regulation and fuel management components that go between those components,” he said. “So, everything associated with storing fuel right through to delivering it to the engine for combustion.”

Volvo and Westport have been long-term partners since before the JV, with Volvo selling about 6,000 trucks – mostly in Europe – with the HPDI fuel system running on liquefied natural gas (LNG). Those trucks have performed well, according to Lars Stenqvist, Volvo Group’s chief technology officer, and continue to be produced for the European market today.

“LNG is important,” he said. “It is still a fossil fuel, but it can and will play an important role as a transitional fuel. If you choose LNG as a fuel compared to diesel, you will immediately reduce your CO2 emissions by 20% and 20% is a huge step for us in society. We need those kinds of steps.”

But 20% won’t meet global regulations striving to eliminate emissions from heavy-duty transport, so the future of HPDI is likely to be hydrogen.

Volvo continues to tout internal combustion engines (ICE) as one of three paths to meeting zero emissions – which it intends to achieve with all its newly built trucks by 2040 – but fossil-free fuels such as hydrogen will be required.

“There is so much potential with this technology when it comes to hydrogen,” Stenqvist said, “and hydrogen plays a vital role in our long-term decarbonization [objectives].”

Volvo also believes in hydrogen fuel cells and has formed a joint-venture with Daimler called cellcentric – also based in B.C. – to develop fuel cells. But Stenqvist said fuel cells won’t be the answer for all customers in all regions of the world.

While Baker throws no shade at fuel cells (“We absolutely expect that fuel cells will be a key part of the decarbonization strategy,” he said in an interview with TruckNews.com), he also touted key advantages of the HPDI fuel system that can contribute better efficiency and performance.

The HPDI advantage

“We have demonstrated across multiple different OEM engine platforms significant improvements in thermal efficiency, fuel economy and power density without exceeding any mechanical limits of the base engine,” Baker said.

For the more technical-minded, he expanded: “We achieved a 30-bar BMEP (brake mean effective pressure) at north of 50% brake thermal efficiency, which are just a ridiculous combination of attributes. To put some more tangible numbers to that for people who don’t do this every day, we demonstrated on a 13-liter engine platform, 600 hp and 3,000 Nm (2,213 lb.-ft.) peak torque all while achieving 50% thermal efficiency.”

He also said HPDI improves fuel efficiency by 1-2%, all while retaining diesel-like reliability and durability, something Baker said fuel cells have not yet proven capable of doing under real world demands.

“By changing the fuel and the fuel system, we can leverage all of that and deliver extremely cost-effective, very significant decarbonization,” he added.

However, a potential hurdle for HPDI is that it’s not considered by some regulators to be a completely zero-emission solution. Certain lubricants within the system produce trace amounts of tailpipe emissions, as does a pilot fuel – currently diesel in most cases – which requires afterteatment for NOx and particulate matter control, despite minimal consumption.

Because the tailpipe emissions are reduced by 97-98% compared to today’s technologies, European regulators have, within the past couple months, redefined their CO2 emissions regulations set to come into effect later this decade to allow for up to three grams per tonne/kilometer of CO2 tailpipe emissions. This paves the way for the widespread adoption of HPDI hydrogen.

“The analysis we, and some of our OEM partners including Volvo have done, demonstrates that a hydrogen heavy-duty truck powered by HPDI hydrogen can in most cases comply with that three gram per tonne/km zero emission vehicle designation,” Baker told TruckNews.com in an interview.

“It depends on the payload of the vehicle and the configuration of the vehicle – including things like rear axle ratio, for example. But our analysis and that of some of our current and prospective OEM customers is that the vast majority of heavy-duty trucks are expected to comply with that three gram per tonne/km threshold when powered by hydrogen HPDI.”

Europe is the first global region to make such a provision and Baker said he’s hopeful the EPA and CARB, who regulate emissions in North America, will follow suit.

The truck

The truck displayed at the JV event was a production model LNG HPDI Volvo FH imported from Europe and reconfigured to HPDI hydrogen.

“It’s very much proof-of-concept, not something we worked with Volvo on directly and not how a production-developed hydrogen HPDI truck would look like, the main difference being the fuel quantity,” Baker told a crowd gathered around the truck parked at the UBC hydrogen fueling dispenser.

The demonstration truck had capacity of just 16 kg of hydrogen at 700 bar, which Baker said “is perfectly adequate for demonstrating the performance capabilities but nowhere near production representative.”

Production-ready trucks will need to carry about 80 kg of hydrogen on-board, he acknowledged. “This truck has a limited range but is functional at full power.”

Sarah Goodman, president and CEO of the B.C. Centre for Innovation and Clean Energy (CICE) – an agency jointly funded by the federal and provincial governments and Shell – was on-hand to announce it would help fund the JV’s efforts to double the truck’s range.

“The joint venture, based right here in B.C. will grow our clean economy, expand our exports, and build and retain intellectual property right here at home, all the while offering the world a solution to decarbonizing heavy transport,” she told the audience.

The funding, added Baker, will go toward developing an on-board hydrogen fuel compressor and high-pressure hydrogen fuel storage cylinders so the truck can achieve the range needed in real-world applications.

While the truck on display – and most other hydrogen-fueled trucks seen in the market to date – is a cabover design, Baker said in an interview “There’s absolutely nothing that precludes us from applying the technology to conventional trucks for the North American market. In the case of the truck you saw today, the hydrogen HPDI truck, it was purely availability and logistics that dictated [it being a cabover].”

Volvo’s new VNL platform – designed to be its future platform for all technologies – will be able to be fitted with the hydrogen HPDI fuel system, confirmed Stenqvist. And it won’t be limited to Volvo trucks, either, once the JV’s technology enters production.

“You should not strive for exclusivity.”

Lars Stenqvist, Volvo Group

“We made it clear from the beginning when we set up the joint venture around HPDI technology, that we are doing this in order to increase volumes for this technology,” he explained.

“Of course, we want to increase the volumes in the Volvo Group. But we are also looking for other external customers. We would love to have a few, or all of, our competitors on-board this journey as well because everyone would benefit from getting the volumes up on this technology and getting the program costs down.”

Rolling it out to the industry at large, he added, would benefit the environment as well. “You should not strive for exclusivity,” Stenqvist emphasized, relating to technologies that can help the transport industry eliminate its carbon footprint.

Have your say

This is a moderated forum. Comments will no longer be published unless they are accompanied by a first and last name and a verifiable email address. (Today's Trucking will not publish or share the email address.) Profane language and content deemed to be libelous, racist, or threatening in nature will not be published under any circumstances.

performed well, according to Lars Stenqvist, Volvo Group’s chief technology officer, and continue to be produced for the European market today.

“LNG is important,” he said. “It is still a fossil fuel, but it can and will play an important role as a transitional fuel. If you choose LNG as a fuel compared to diesel, you will immediately reduce your CO2 emissions by 20% and 20% is a huge step for us in society. We need those kinds of steps.”

I have copied a few lines in your article which stated that LNG is a fossil fuel. That is correct when talking about natural gas obtained from drilling. However, Renewable Natural Gas is a different entity. It is produced from organic waste and is NOT a fossil fuel. In fact, it is the only Carbon Negative fuel that is available. All RNG produced is actually captured methane from organic waste that would otherwise be released to the atmosphere from agricultural waste, food waste, landfill gas, and sewage waste. RNG is most of the natural gas used for transportation as opposed to fossil natural gas.